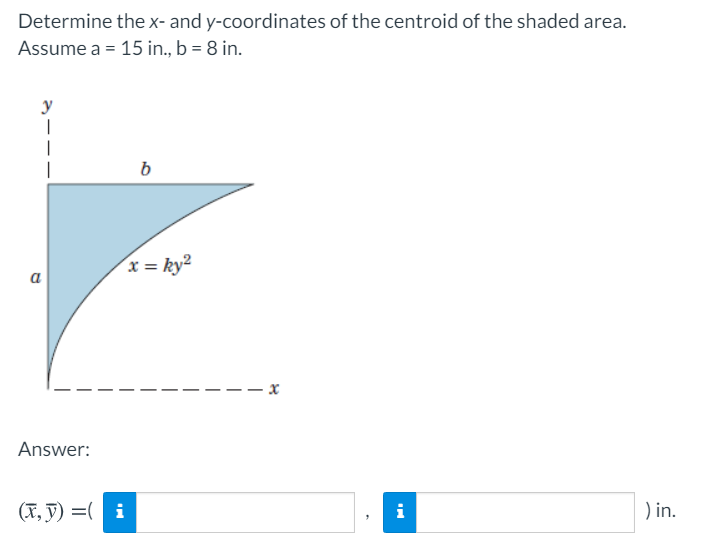

It will be easier to understand the above with an example. G59: Select Workpiece Coordinate System 6 G58: Select Workpiece Coordinate System 5 G57: Select Workpiece Coordinate System 4 G56: Select Workpiece Coordinate System 3 G55: Select Workpiece Coordinate System 2 G54: Select Workpiece Coordinate System 1 But during program flow, you may change a WCS system. When you start programming, the WCS 1 is by default the first WCS to be taken into account. They are pre-defined from the settings of the controller. The WCS for a normal controller can be up to 6, named WCS 1, WCS 2 and so on. In the attached picture p9.jpg, you can se four different WCSs for a table, each one declared on each corner of it. This is done because there may be more than one program zero points to be used. So, we define the WCS as follows:Įach machine has more than one WCS.

We do this because it is easier to have reference from this position, rather than the machine zero point. In the attached picture p8.jpg for example, we need to adjust the program zero point in order to be at the top left side of the paper.

This is done using the WCS (Workpiece Coordinate Systems). Now it is necessary to somehow declare the programming zero point in respect to the zero point. The program zero point for X-axis for example is different than the machine zero point of the X axis and this happens because the limit switch could be placed anywhere on the body of the machine. In an ideal world, the actual zero position of each axis would be the same as the zero point. That’s why the zero cycle is necessary. When you turn on a CNC, it does not know it’s actual position on each axis. Now the machine knows exactly where it stands. For the X axis for example, the machine will slowly move the X axis until it reaches the X axis limit switch. What is this zero cycle? Simply, the machine will slowly move all their axis to meet some limit switches. It will not start until it has complete the zero cycle. When you start up a machine, it will ask you for a zero cycle***.

0 kommentar(er)

0 kommentar(er)